One of the biggest problems with hardware, regardless of whether they are peripherals or components, is the amount of material that ends up being thrown away. Ideally, it should be recyclable or biodegradable. The first can already be done under complex processes. Well, they have managed to invent the paper pcb and for certain applications it can become a revolution.

The manufacture and design of highly complex hardware is in the hands of a number of companies that can be counted on the fingers of one hand. However, there is a world apart from people who create their own systems to use them on a small scale with very low power and consumption systems. In this world, one of the biggest existing problems is the creation of the PCBs where the chips are placed and that can be a tedious process if it is done from home or long days of waiting if they are commissioned from a third party.

How useful are paper PCBs?

PCBs are usually a mixture of resin and other materials, which have a complex design and creation process, especially for those who create their own peripherals for specific solutions. That is why the fact of being able to easily print the board to which the chips will be connected from a simple printer is a process that facilitates the task. However, in this case we are not talking about removing the paper PCB from your home, but rather the process is more complex.

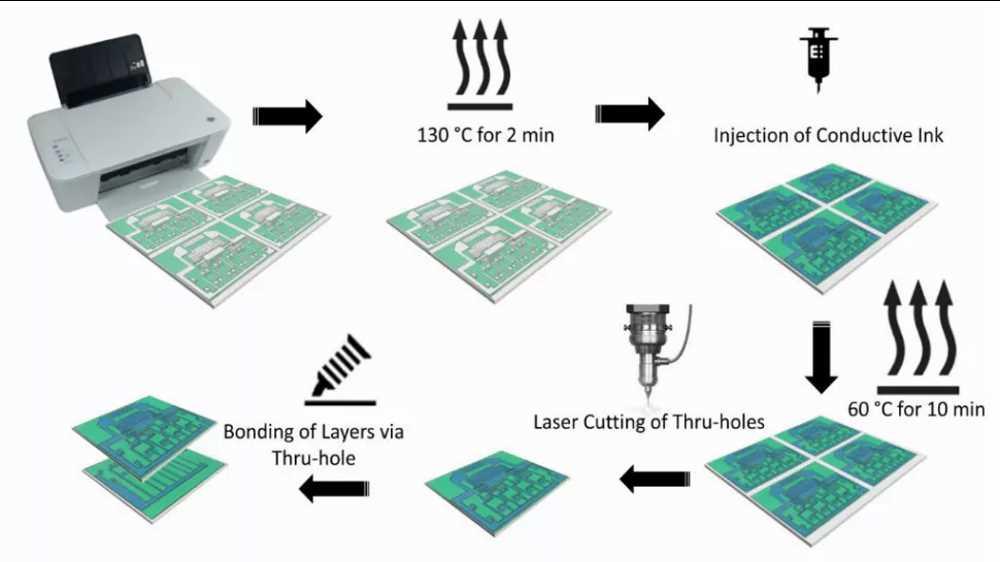

- The pattern of the PCB you want to achieve is printed on waxed paper.

- It is heated up to 130 °C for two minutes.

- In the part where the wiring is printed, ink that conducts electricity is used.

- Reheat to 60°C for 10 min.

- With a laser the design is just polished.

The trick is not precisely in the paper, but in the ink used to create the pathways through which the different elements mounted on the plate communicate. However, as you may have deduced, they cannot be used on all types of hardware devices, for more than obvious reasons.

What applications does it have?

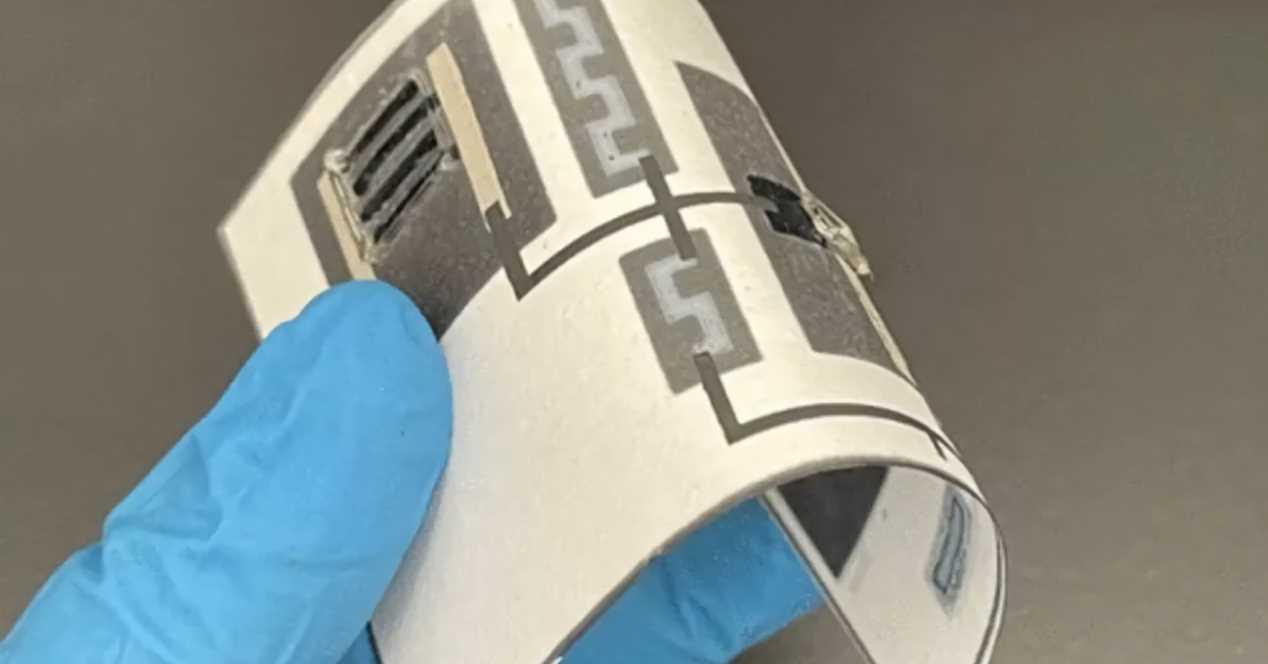

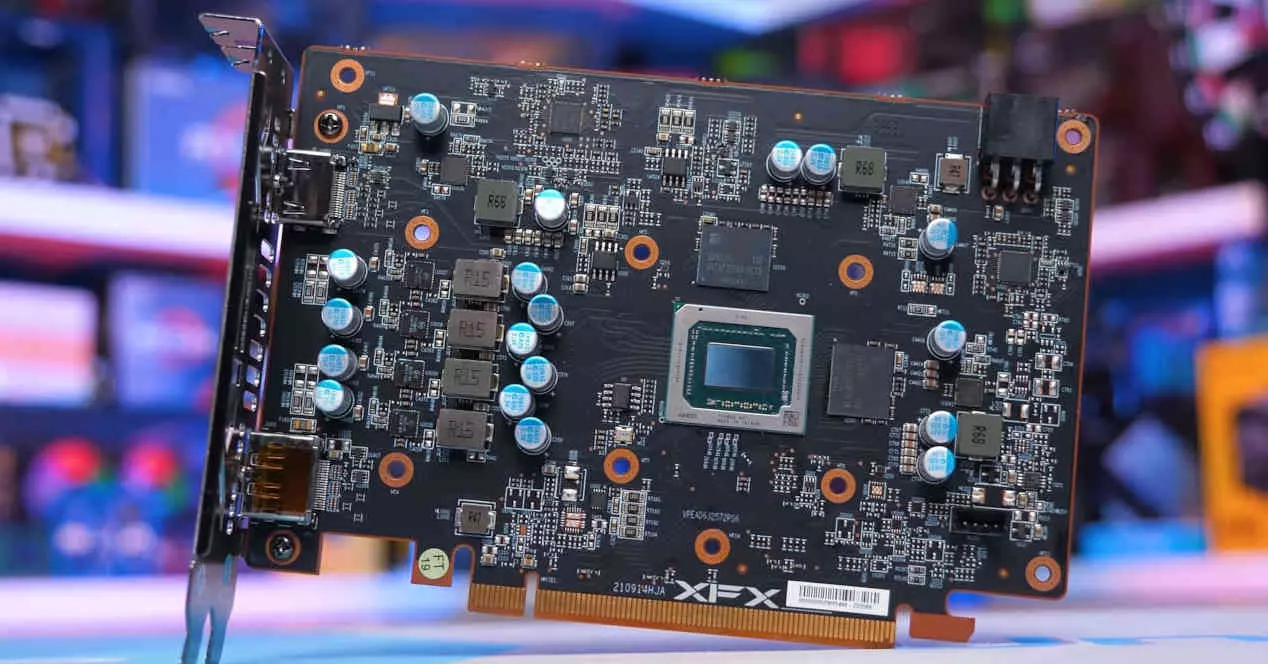

To get started, Forget seeing a paper PCB on things like your computer’s motherboard or a graphics card. Its utility is designed for very low power chips. Like those used in IoT-type devices, wireless sensors and everything that requires very little energy to work, such as the systems used to monitor the health of patients in a hospital, track goods in transport. The fact that using a material that is not rigid gives them great versatility, but also the problem that they have to be protected against extreme humidity.

The good part is that its use can reduce a large amount of disposable electronics. Especially in hobby projects where chip consumption is extremely low. In addition, that it can generate a new industry. What do you think of this invention?