If you have been using an AIO liquid cooler for years, you will have gone through several phases with it. The first is jubilation or joy at seeing a better performance than with your air cooler (provided it is optimal), the second goes through a period of stability, the third due to a worsening of temperatures and the fourth, unfortunately, is the death of it. Why is this happening?

The failures of a series AIO liquid cooler

We discussed this topic a long time ago and we return to it now that there is more data and a more specific study on it. Although not all AIOs are going to die sooner or later (a heatsink lasts longer), a large number of them will, especially the best-selling ones that correspond to the cheapest ones. The reasons are the same in all of them: costs, materials, time.

Over the years we have been seeing how the coldplate jets had a series of residues that hinder the flow and end up destroying the pumps, some sediments that should not be there and that nevertheless with the passage of time remain there and they are the main fruit of RMA in brands.

Why don’t they fix it? Well, because they are immersed in a price war to sell more, as simple as that. Lower budget per unit means worse materials and compounds. Cutting a radiator through its tank we can see the problem. The vast majority of AIO liquid coolers have common faults that can be seen as soon as we cut the radiator on one of its sides.

Aluminum and solders together with liquids

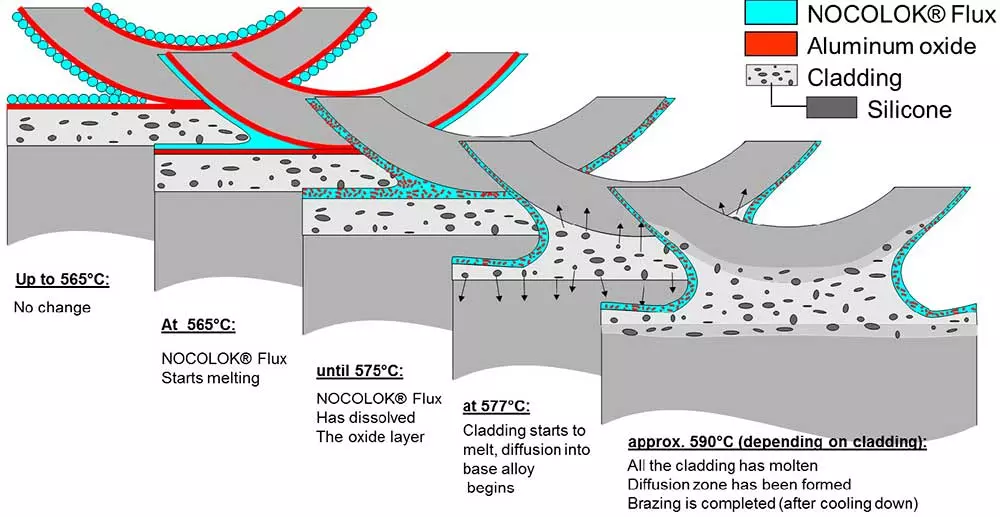

There are two factors that end up destroying the AIO, the compounds with which the radiators are welded and the low quality liquids. The welding of low-quality aluminum radiators is done with a flux based on potassium fluoride mixed with a part of aluminum, this compound being cheap and of poor quality simply to reduce costs.

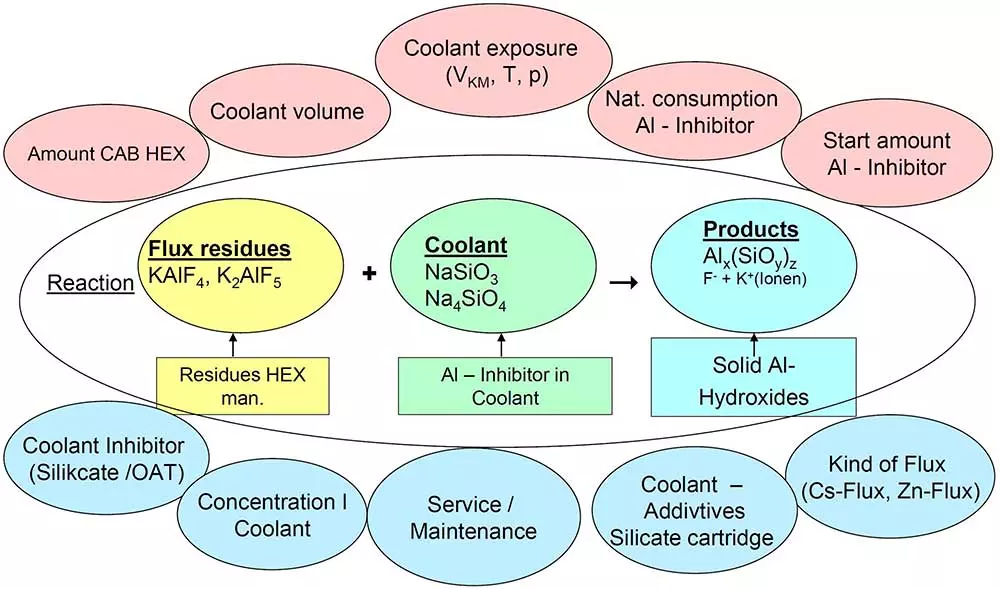

The problem is that this flux is corrosive and generates a residue that, together with a low-quality liquid, results in a slow oxidation of aluminum and a kind of gel that becomes embedded in the radiator pipes and ends up in smaller particles traveling the circuit and finally at the ends of the coldplate.

The oxidation of aluminum and its corrosion are produced by the protection additives against said corrosion, that is, they do not help as such to prevent the disaster because the solders and their flux react to the silicates of the liquid, which is normally a large part of Ethylene Glycol, and a minimum of inhibitors and distilled water in proportions of the 90%-95%, 2%-7% and 0-3% depending on the manufacturer.

Of this large percentage of Ethylene Glycol, almost half is water and the rest is different types of alcohol, which also implies corrosion in the tubes in lower quality models, further aggravating the problem if possible. To this we must add that due to cost reduction, radiators, tubes, pumps and coldplates are not simply washed prior to assembly or distribution, which adds more particles to the equation.

Conclution

In short, quality comes at a price, not all AIO liquid coolers are going to fail, but this depends on expensive compounds, materials and assemblies that the user is usually not willing to pay for. If we add to this details such as RGB fans, various controllers and the R&D that such a system entails, the price war is served and not for the good, which is why the user always prefers something cheaper, not being aware of the problems that may have in the future.