It may not be understood in the first place after the varied news that we have been giving about the improvement in the FABs and in the delivery times of the chips. But as in everything there is an explanation for this and to give it we have to exclude Intel, TSMC and Samsung from the equation, because outside of that the chip crisis has worsened: a 50% more delay than in 2021.

Do you think that the situation will be solved next year as Intel said? Well, it seems that it will not be like that, and that the company did not refer to itself since they hardly have supply problems as they are the largest giant in the industry. Apart from this and according to the sources, the researchers are finding a bleak picture.

Without reaction and production capacity

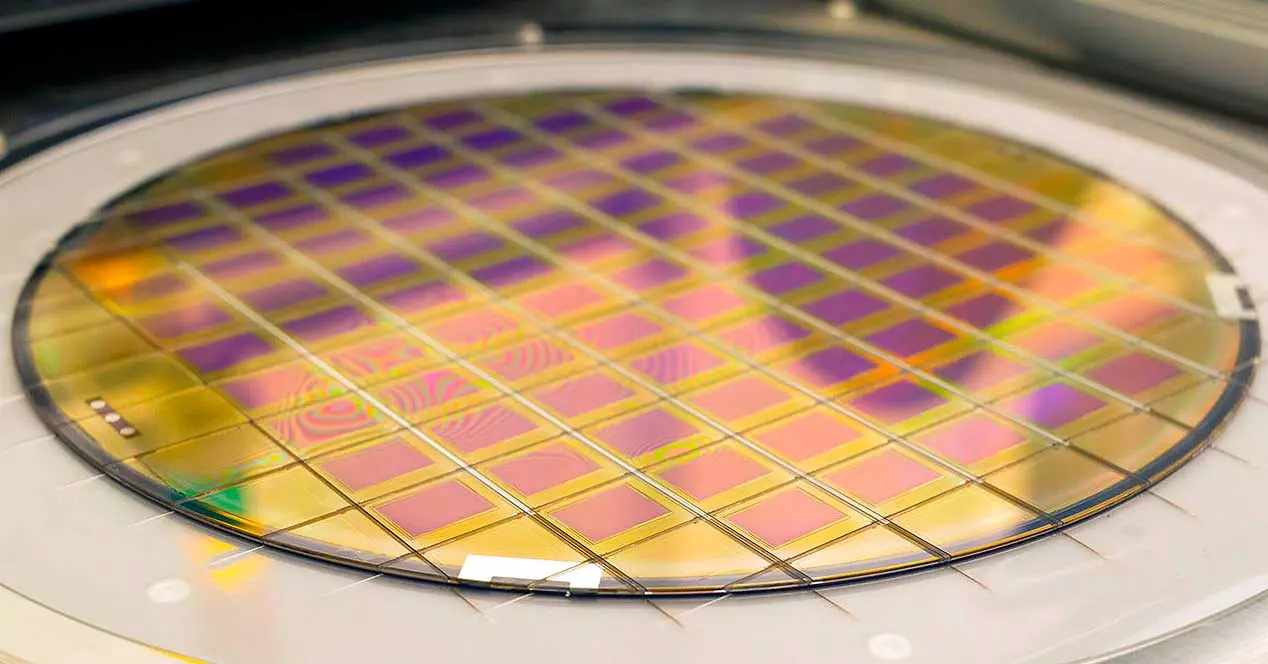

The truth is that these market researchers observe several main problems in the industry. The main one is that the expansion of companies and their larger wafer FABs in terms of nanometers has hardly improved.

Demand continues to grow and these companies are in trouble because, as they say, “the bull has caught them.” The crisis began with the big FABs and now it has reached the small ones, which, on the other hand, have not known how to move as the three tenors have done. The data is very illuminating: a 13% more production capacity for chips to 28nmbut beyond this lithographic process and especially for those FAB with 40nm or higher the capacity has only been increased by one 4%.

The result in the first instance for those clients of these companies has been devastating for the balance of their quarterly accounts: an increase in the average price of a fifteen% for these chips.

Chip crisis worsens: +50% delay

Let’s not forget that everything around us has chips and as such, is subject to an industry that is reeling from the times. The researchers went further and cite verbatim that autumn 2021 was much better than this first quarter of 2022. To be specific, they speak of quite worrying figures: the delivery time has increased by 15 more weeks, where certain basic processors have terms of 44 weeks , that is to say, 10 months.

The average statistical result is even more worrying: the industry has increased the average delivery time by fifty%that is, the delay from when the order is placed until it is delivered has grown by that percentage.

But there is more, because as in all sectors there are key players. In these chips that are essential and their demand is skyrocketing, the delay amounts to a whopping 99 weeks in the worst case. Or what is the same, more than two years since a company requests a certain volume until it can be delivered for installation along with other components.

Therefore, 2022 is being a worse year than 2021 and it does not seem remotely that this is going to end in 2023, at least for the industry as a whole. Perhaps Intel, NVIDIA, AMD, Apple, TSMC and Samsung will come out of the crisis, but they will continue to rely on FABs and external chips for their products, hence why Intel has moved to buy Tower Semiconductor.