The answer to the shortage of chips and the rising costs of manufacturing them is the use of old lithographs, according to Samsung. Which has decided to expand its production capacity in them for the next few years. What does this change mean in the world of semiconductors and why is it not an isolated trend of the South Korean manufacturer?

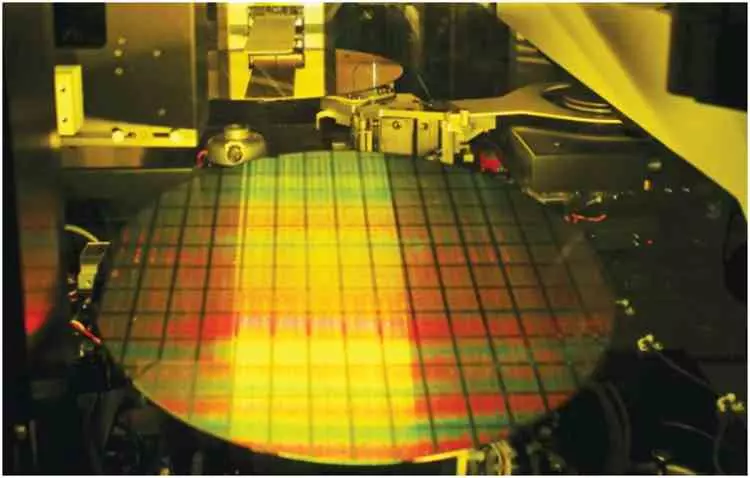

When we talk about lithography we are referring to a synonym of nodes in the manufacture of a chip. Since from time to time technology allows smaller chips to be made, which can not only house more complex structures under the same space, but also achieve higher clock speeds or lower consumption. However, for some time now, the economy of scale has slowed down and while during several lithographic processes there was a correlation between the cost of wafers per area it has remained stable, in recent generations it has become more expensive.

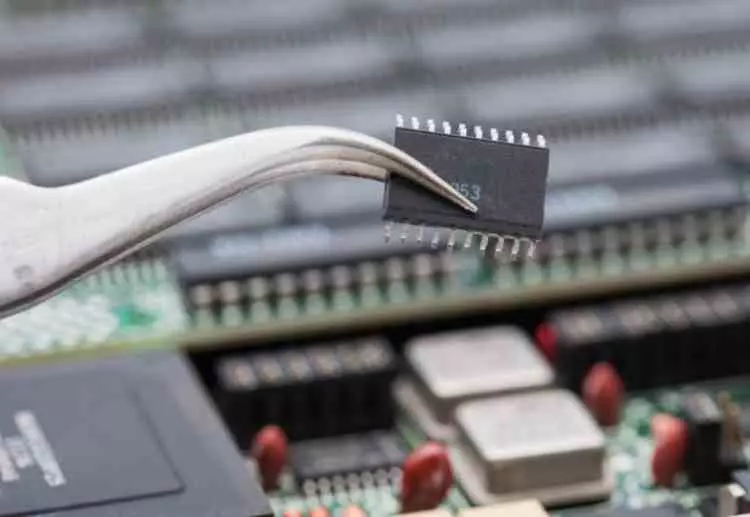

This is why for certain performance levels and for use in certain products, the hardware industry is not making progress in lockstep with the use of the most advanced lithographs. Especially since not all parts of the processor need them and they are not a cost advantage. Being one of the reasons behind the future use of so-called chiplets, where a processor will be divided into several chips instead of just one. The advantage? Being able to use less advanced nodes for the manufacture of certain components.

Samsung has plans for its old lithographs

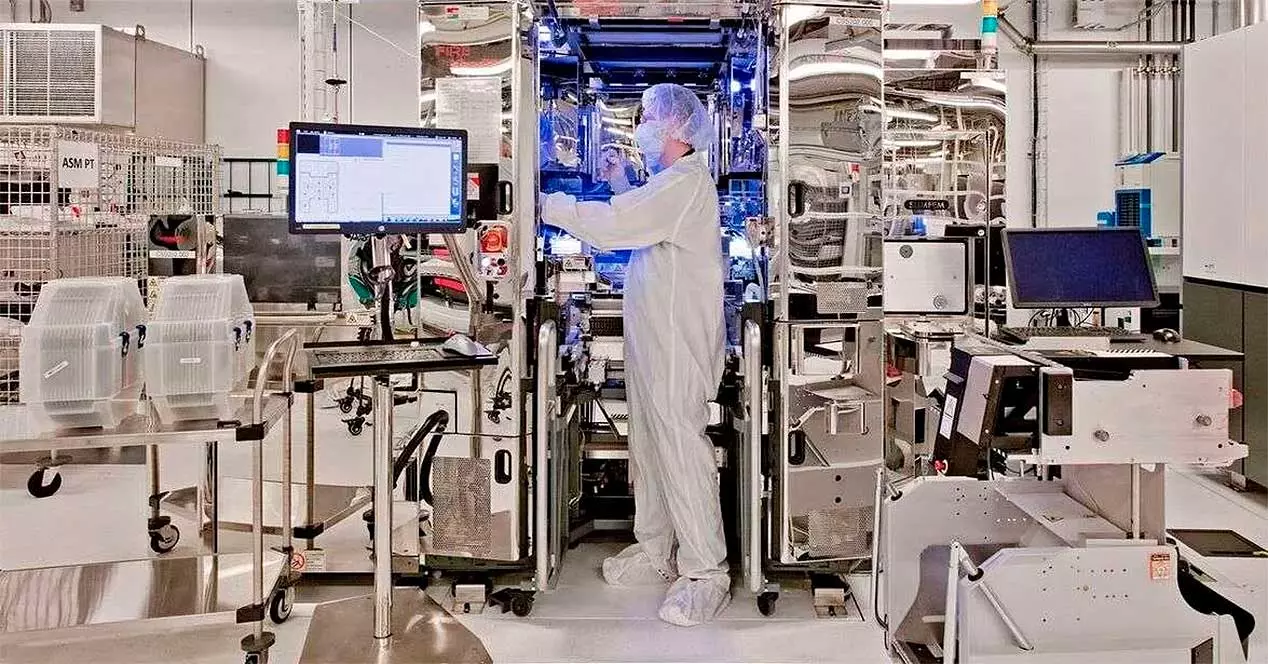

If we talk about the three great foundries that remain in the world, the third in discord would always be the Korean multinational, whose strong point has been the manufacture of memories for years, but is also dedicated to the production of chips both for its own use and for third parties. However, until now it was a trend for the leading manufacturers to go to more advanced manufacturing nodes.

Still, the shortage of chips and the high costs of new components based on newer manufacturing technologies have opened up a business opportunity for old Samsung lithographs. The idea would be none other than take advantage of the shortage due to the continuous shutdowns in China due to COVID-19 to manufacture much simpler components, but which are crucial in the manufacture of various hardware products. Let’s not forget that the old manufacturing processes are not only more optimized than the new ones, but they are also much lower.

Since the rest of the foundries lag behind the top three, they tend to integrate the new manufacturing nodes much later. This is the case of the Chinese SMIC and the Taiwanese UMC, which will be negatively affected. Especially the latter because there is a lock on the former. So we are approaching a period where the commercial life of chips, especially in older lithographs, will be much longer. Let’s not forget a maxim for the consumer market in passing: “you don’t buy the technically best, but the good enough”.