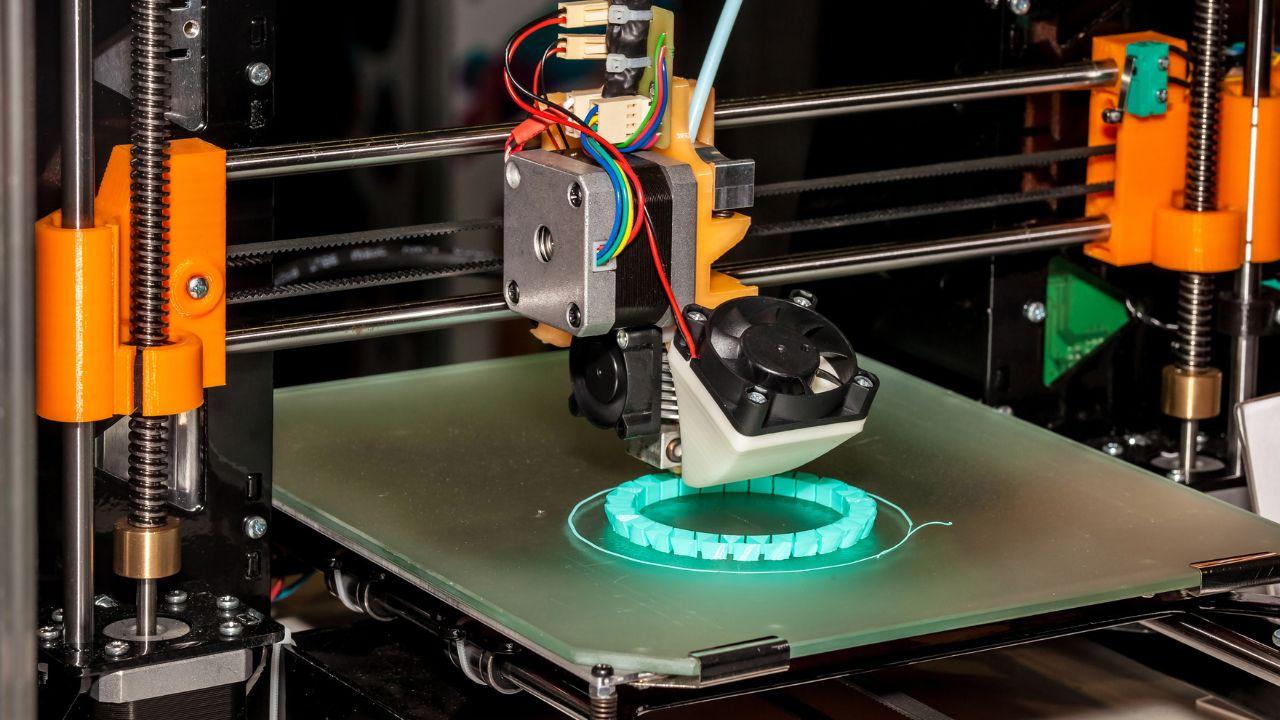

To help you with this problem, we are going to tell you the melting temperatures of different filaments. It is important that before buying it, you always check its specifications. The temperature at which the material melts should always appear. If this is not the case, it is better to look for another seller, since it is a very important parameter.

We are going to tell you the times of the most common materials and the temperature ranges at which they melt.

PLA (polylactic acid)

It is currently the most popular for its ease of use, being non-polluting and being biodegradable. It is obtained from corn starch. Has a casting temperature oscillates between 180 ºC and 230 ºC. Due to these temperatures, it is compatible with all extruders on the market.

ABS (acrylonitrile butadiene styrene)

It is also very popular and widely used in the mobile phone or automobile industry, among others. It is characterized by being quite flexible and offers good resistance to blows. In addition, it supports (after handling) temperatures between -20ºC and up to 80ºC.

But, this material has certain drawbacks. The first of all is that it is toxic, so it must be used in a well-ventilated area or, failing that, in a closed 3D printer.

Requires this filament of temperatures between 210 ºC and 250 ºC for your foundry. You should know that it tends to deform when it cools, spoiling the piece.

PETG (polyethylene terephthalate)

Material used for the manufacture of plastic bottles that we can find in the supermarket. It is of the inert type, being ideal for manufacturing parts that are in contact with food. It offers good resistance and is semi-rigid. It does not release odors during printing.

Being 100% recyclable, many users collect bottles to make coils at zero cost. Many opt for the blue bottles of a well-known brand of water.

This material melts casting temperatures between 220 ºC and 250 ºC.

Nylon (nylon)

Quite interesting filament for being the one that offers the most hardness, flexibility and durability. Mostly, it is used in industries. It has the problem that it is complicated to use and must be in open spaces.

It requires some operating temperatures between 240 ºC and 260 ºC.

PC (polycarbonate)

This is a material widely used in engineering applications. It has the ability to withstand high temperatures, although as a negative aspect, it tends to absorb moisture from the air. This aspect forces you to store it in hermetic containers so that it does not lose performance and resistance.

It presents a great problem of use in 3D printers and it is that it requires temperatures between 270 ºC and 310 ºC to melt.

TPU (thermoplastic polyurethane)

Quite flexible and durable material that is used in the automotive industry. It is a derivative of rubber (TPE) that offers greater rigidity and durability. It is usually used to make smartphone cases.

The good thing is that it requires casting temperatures between 210 ºC and 230 ºCquite similar to PLA.

ASA (tocrilonitrile styrene acrylate)

It is similar in characteristics and properties to ABS, but offers greater resistance to UV rays. It is an excellent material for making pieces that will be outdoors, although it absorbs a lot of moisture. We must emphasize that it is toxic, so we need ventilated spaces or closed 3D printers.

There are two types, which affects the casting temperature:

- Unannealed: between 77ºC and 102ºC

- Annealed: between 88ºC and 104 ºC

Summary of filament melting temperatures

| Material | Temperature |

|---|---|

| PLA (polylactic acid) | Between 180 ºC and 230 ºC |

| ABS (acrylonitrile butadiene styrene) | Between 210 ºC and 250 ºC |

| PETG (polyethylene terephthalate) | Between 220 ºC and 250 ºC |

| Nylon (nylon) | Between 240 ºC and 260 ºC |

| PC (polycarbonate) | Between 270 ºC and 310 ºC |

| TPU (thermoplastic polyurethane) | Between 210 ºC and 230 ºC |

| ASA (acrylonitrile styrene acrylate) | Unannealed: between 77ºC and 102ºC Annealed: between 88ºC and 104 ºC |

Conclusion

Before buying a filament you should know the temperatures at which it melts, since not all of them are the same. You should also know how hot the extruder nozzle can get. If it is above that of the material, it is not a problem, we can easily regulate it. But, if the nozzle is below the temperature of the material, the thing will end in disaster.