The main chip manufacturers such as TSMC, Samsung or Intel, are constantly evolving their manufacturing systems with the aim of continuing to make the transistors of the chips smaller and smaller, something that allows increasing their density (putting a greater number of transistors in the same space) and thus increasing the efficiency of their products.

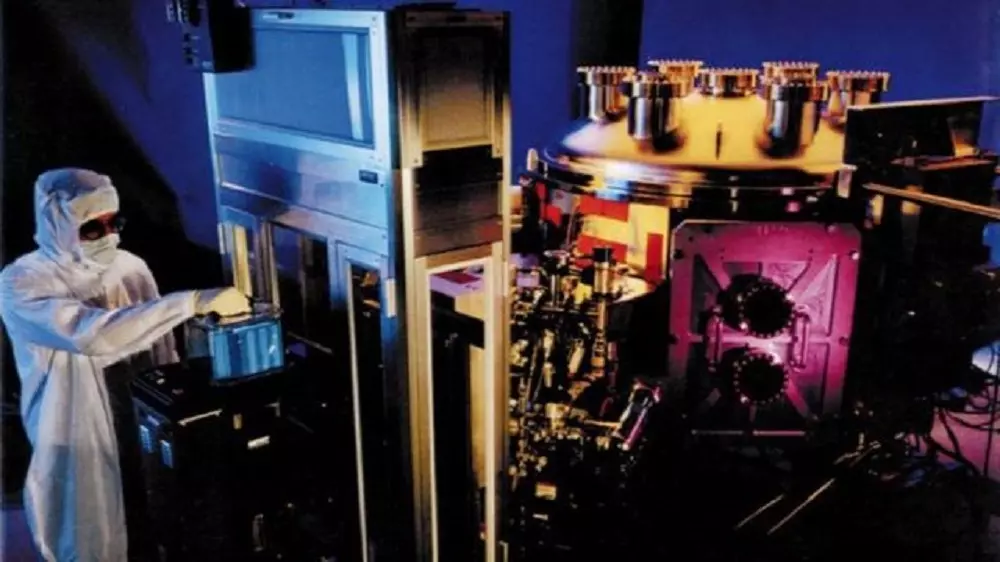

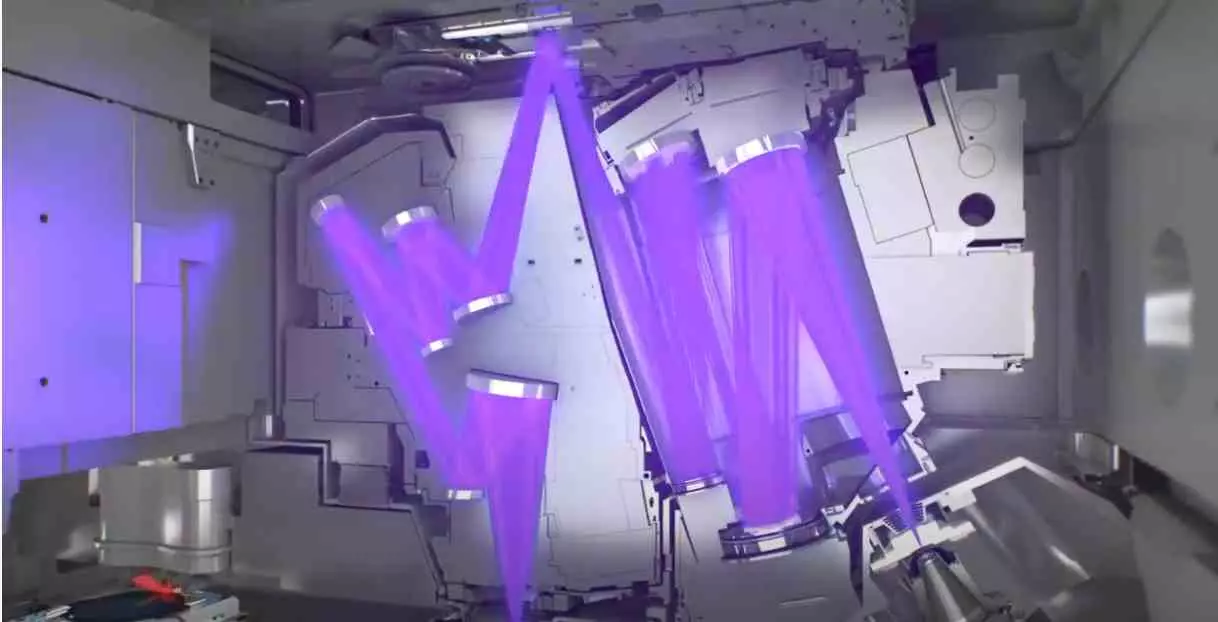

EUV lithography seems like the panacea of the current decade to achieve this, but the main problem it has is that only ASML manufactures the machines capable of carrying it out, extremely complex and extremely expensive machines that have, of course, the disadvantage that increase manufacturing costs.

RAM made with EUV will arrive in 2024

As we said a moment ago, it was Sanjay Mehrotra, CEO of Micron Technology, who has confirmed in an interview that the company has already incorporated EUV technology into its DRAM manufacturing plan, and in fact has also confirmed that they will begin to introduce it. from the 1γ (gamma) process node to its 10nm chip generation.

Therefore, Micron’s first DRAM chips made with EUV for RAM and SSD will initially be manufactured at Micron’s Taichung A3 plant, and are expected to enter mass production by 2024; if all goes well, this also means that the first RAM and SSD products with EUV chips at 10nm would hit the market at late 2024 or early 2025, and we would already be talking obviously about DDR5 RAM.

Even before this disclosure by Micron, other manufacturers such as Samsung or HK Hynix have already been looking into EUV technology to make their memory chips, and in fact they have already implemented EUV lithography since late last year. The difference between these two manufacturers and Micron is that they have not given a date estimate, so now for the first time we already know when it will arrive.

What are the implications of DRAM made with EUV?

As we mentioned at the beginning, one of the biggest problems with EUV lithography is the large production cost implying; the machines are created exclusively by the Dutch company ASML, and the cost of each of these machines is several million euros. In addition, the problem not only lies in the cost of the machine itself, but also in the dozens of adjustments that must be made to adapt its characteristics to the type of production they need to do with it, something that also entails a great cost both in terms of workforce and time as in means.

This means that there is a good chance that this increase in the cost of production will directly impact the prices of the products, or in other words, it implies that RAM and SSD products made with EUV technology, they will be more expensive.

However, this is not totally negative either, since introducing a lithography such as EUV in DRAM chips also means that the density of the chips will be increased, thereby offering more expensive RAM and SSD memory, yes, but also with higher capacities. , ultimately resulting in better capacity / price ratio.

There are still at least three years to go before we reach this inflection point in the industry, and until then a lot can happen, so we cannot predict anything at the moment: we will have to wait to see how the technology evolves, how it will manufacturers with this EUV implementation, and how the price of DRAM memory in the market at this time, because as you are sure by now, it is quite volatile in this regard.