New methods for making chips make it possible to create them with much smaller transistors and therefore fit more within the same area. This brings us to a simple question: Why don’t NVIDIA and AMD release downsized versions of their existing chips for the more modest ranges? Well, this, even if you don’t believe it, has nothing to do with a marketing strategy, but with something that all chips have, the so-called microbumps.

The logic of Moore’s Law is that if I have a 10mm long square chip, let’s set it to 10nm to keep things simple. So, if I make a 7nm version of the same chip, it will become 7mm long and therefore go from 100mm.2 area at 49 mm2 and consequently it will have reduced its size by half. However, this is not possible due to the fact that the chip needs to maintain its ability to communicate with the outside and unfortunately, that part does not scale in the same way. That is why we are going to introduce you to what microbumps are.

Why don’t we see smaller CPU, GPU, SSD or others?

The arrival of large graphics cards like the RTX 4090 can lead us to ask a completely logical question if we take into account how the evolution of chips works over time. What’s more, there is a tendency to miniaturize things so that they take up less and less space. However, we do not see memory modules of reduced size, nor SSD drives and processors either.

And we should logically see them, since having smaller transistors means not only making more complex chips, but also being able to reduce the size of those that already exist. Let’s not forget that the specifications of many products are already good enough in performance. Therefore, they have to find their appeal in another way and the normal thing would be to have increasingly compact systems, instead, we find that they are gradually disappearing.

And all of this is not due to simple whims, but to the fact that when we usually talk about scaling chips, whether logic or memory, we don’t talk about an element that has to do with the interconnection and communication of the themselves.

What are microbumps on a chip?

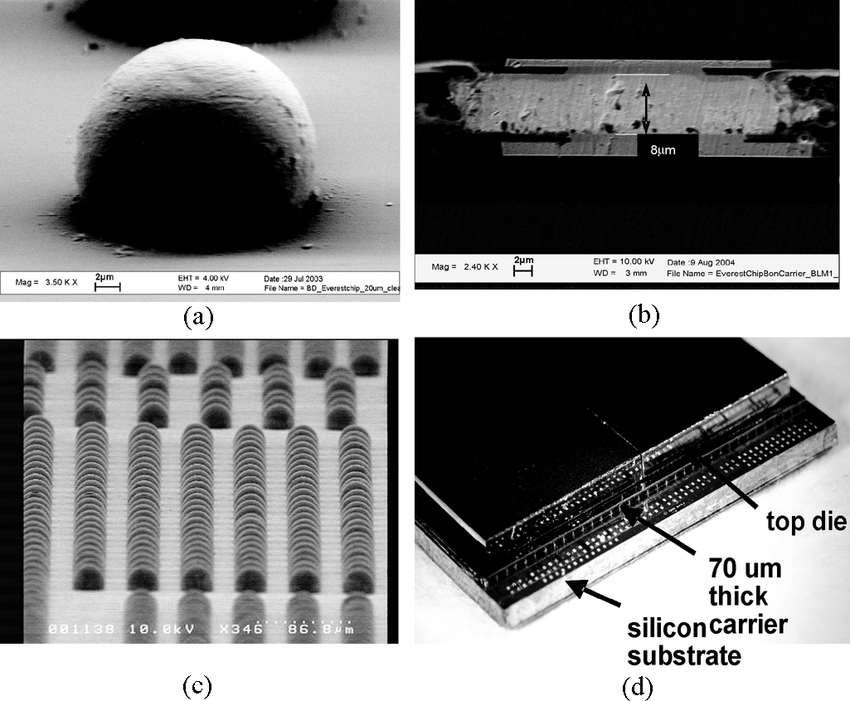

Many of you will have seen unsoldered chips that have a matrix of pins at the bottom that are usually soldered to the board. Well, the job of these connections is to communicate the chip with the PCB and, therefore, with other chips, the voltage lines that come from the power supply, and so on. These connections are the ones that later, when soldered to the board, look like small copper balls, and that in the end are nothing more than connection pins. That is why when it comes to undoing them and redoing them again, we call the process reballing. Actually, we should call it remicrobumping,

The problem is that they do not scale in the same way as transistors, so if we reduce the size of the chip we will also have to take into account that we will have fewer connections available. This means having to share the microbumps for different functions, which ends up causing contention problems when accessing information. Neither can the bandwidth be maintained due to the fact that this would mean increasing the clock speed of the interface and with it its voltage, power consumption and heat.

It is for this reason that when designing a chip such as the GPU of a graphics card or a new type of memory, the number of connections or microbumps is usually left fixed and with it the size of the chip. It is not intended to make a cheaper and smaller version of an already existing chip due to the problems that we have just mentioned. This is why, for example, NVIDIA has not released its RTX 30 series from Samsung 8nm to TSMC 4nm. Neither has AMD with its RX 6000.

The problem of old chips

What happens with chips that are very old? Since it gets to the point where we have so few transistors to scale per area, it doesn’t make sense to build them on a more advanced node, as you end up paying more for wafer cost without being able to benefit from a smaller transistor. That is why there are still factories with less advanced manufacturing nodes that make less advanced integrated circuits, but they are essential for multitudes of industries.

What’s more, part of the regionalization plans that consist of not depending on the Asian chip factories to build them in the European Union and in the United States are not based on creating the most advanced chip, but on moving the manufacturing of the themselves and have control over production and logistics costs.

Finally, a trend has been that of integration, if a chip is too small to be manufactured in a more advanced process, then several adjoining ones are joined into one. This is something we’ve seen in motherboards, where there are fewer and fewer chips on them, but the specs don’t go down.