Intel and ARM join forces… And who would have thought it considering that they are top rivals in some computing fields, with the latter trying to eat the toast of the former in segments such as personal computers and data centers. The question for Intel is clear: if you can’t compete with your enemy join him.

Intel Foundry Services (IFS) and ARM have announced a multi-generation agreement to enable ARM licensees to manufacture their products (in principle Single Chip Systems, or SOCs) in Intel factories, using next-generation production nodes known as Intel 18A and that it will advance manufacturing processes up to 1.8 nm.

The collaboration will start with mobile SoC designs, which means chips for smartphones primarily, but also leaves the door open to a wider range of applications, including automotive, Internet of Things (IoT), data centers, aerospace and government, probably in defense sectors. Others such as PCs are not mentioned, where Intel (still) dominates with its x86.

Intel IDM 2.0

Announced in the spring of 2021, it is one of the biggest business strategy changes in the chip giant’s history. In essence, it supposes the entry of the company in the business of foundries or what is the same: custom manufacturing of semiconductors for third parties.

The bet is monumental and to begin with Intel will invest 20,000 million dollars in two new manufacturing plants that will be located in Arizona. Others have also been announced in Europe. The strategy also has some geopolitics taking into account that most semiconductor production plants are located in Asia.

the new model Intel Device Manufacturing for supply and manufacturing of chips contemplates three different parts to keep Intel at the forefront of the semiconductor business.

- internal manufacturing. Key to supplying its own processors and reducing the current problems that have led it (for the first time) to outsource manufacturing to external suppliers.

- external factories. Use of foundries such as TSMC, Samsung, and GlobalFoundries for certain products that Intel calls “core computing offerings” for consumers and businesses.

- Intel Foundry Services. Intel will become a foundrie to open up to produce chips for third-party manufacturers.

This third leg of the strategy is the newest and most interesting. IFS will function as an independent business unit and will manufacture chips on behalf of third parties under various architectures, x86 itself, ARM’s for which this important agreement has been announced, and in the future a third, the promising RISC-V.

Why Intel and ARM together? ARM is unstoppable

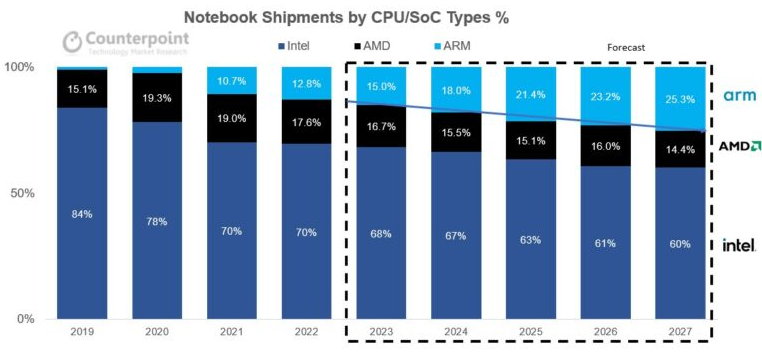

As a temporary curiosity, to say that the announcement of this agreement has come a couple of days after the publication of a report by the Counterpoint analysis firm, where it ensures that portable personal computers based on ARM architecture will grow in popularity and their participation of market it will almost double from the current 14% to 25% in 2027.

Most of the ARM-based equipment will come from Apple and its successful silicon project, for which it precisely replaced Intel. But it’s a matter of time before more of the existing PC OEM/ODMs and also the smartphone makers that absolutely dominate the mobility segment, will follow in Apple’s footsteps, bet on ARM and push this architecture forward. A lot of it is going to depend on Microsoft solving the current problems with Windows on ARM.

That which. It is clear that Intel sees its privileged position threatened and not only by ARM. AMD has become a great rival in CPUs for PCs and NVIDIA does the same in servers with its CPGPUs, which are increasingly used in Artificial Intelligence, deep learning and high-performance computing applications.

The changes in the industry towards other types of architectures such as ARM require a response from Intel. In this case, the saying fits perfectly “If you can not beat them, join them”.