Apple is diversifying its business strategy globally, to reduce dependence on China as (practically the only) strategic partner. After China came India and Indonesia. But Apple, formally and with a contract involved, moves to another country to continue manufacturing. In this post we tell you the details.

Apple’s new destination is already signed

“The lease will be effective until February 2057,” they report from 9to5Mac, citing statements by the South China Morning Post, who have been the ones who have revealed details of the expansion plans in the new Apple location to manufacture products, Vietnam.

While it is true that Apple already manufactured iPad and AirPods models in that country, the company has given the go-ahead, already formally and by signing a contract, to manufacture more products for a long period of time. In this case, the Mac Pro 2023 It would be one of the first “important” products that Apple manufactures on a large scale in that country, they report from 9to5Mac.

“Foxconn has signed a lease to occupy a 45-hectare plot for an approximate amount of US$62.5 million,” reports the South China Morning Post. Through Foxconn, who is currently its largest manufacturer, Apple has completed the operation. In fact, Mark Gurman, an Apple analyst at Bloomberg, already said at the time that the new Mac Pro will be manufactured in Vietnam, they explain from 9to5Mac. But it’s not just Apple that wants to make the iPad, AirPods and the new Mac Pro in Vietnam. Nikkei reported that also the MacBook Pro will start producing in Vietnam. “Apple has taken advantage of its main supplier, Foxconn, to start manufacturing MacBooks in Vietnam from May,” they quoted 9to5Mac.

Apple Silicon has changed much more than we think

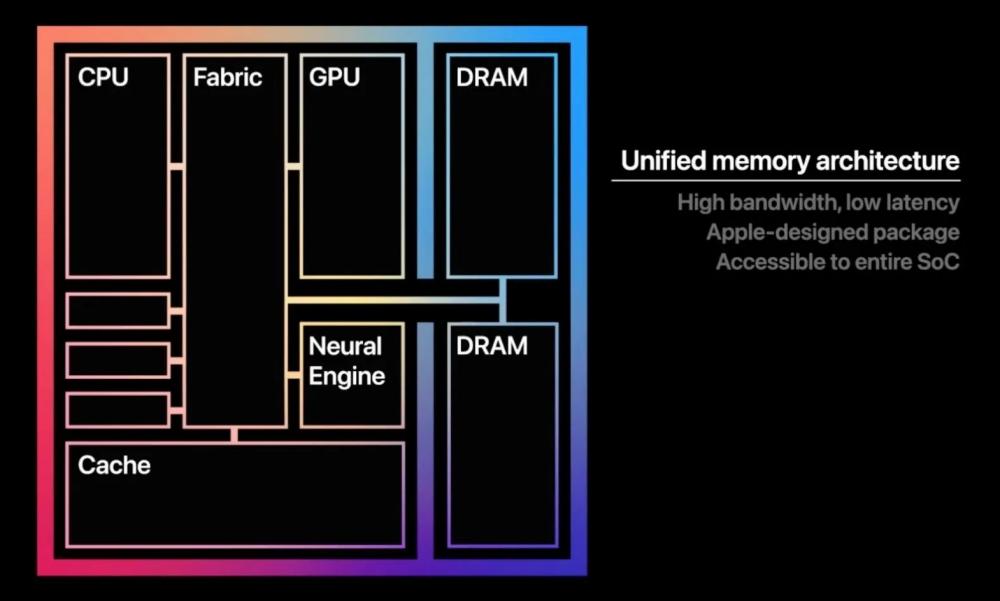

One of the keys by which Apple diversifies the production of MacBooks in Vietnam is due to their design. Thanks to Apple Silicon, current MacBooks they have fewer parts to assemble, which streamlines processes. Unlike Intel processors, where components were manufactured separately and then assembled into more complex circuits, Apple Silicon is a SoC (System on a Chip).

That is to say: if before we had the processor on the one hand, the RAM memory on the other, the graphics processor on the other and the storage memory on the other, now things change. And it is that, in a single plate, we have the processor, the RAM and the graphics processing. What used to be three components is now one. And if we add the storage disk, what used to be four components is now two.

Assembling two components significantly reduces the time and infrastructure required to assemble four components, to get the same number of units manufactured. To this we must add that such a large supply chain is no longer necessary, nor is it necessary to depend on third-party suppliers that have to import raw materials to later manufacture the components, so that they can later be assembled. The whole process is significantly reduced. For users, we have higher performance at lower cost. But exactly the same thing happens “from behind closed doors”: higher performance and efficiency (in production) at a much lower cost.