The processors and GPU of the graphics card are made in silicon, mostly than melts To over 1400ºC. Something that not everyone knows is that other materials are added in current manufacturing processes. The reason for the limit of 100 ºC is really in another point that you can’t even imagine.

Where does the 100 ºC limit come from in processors and graphics?

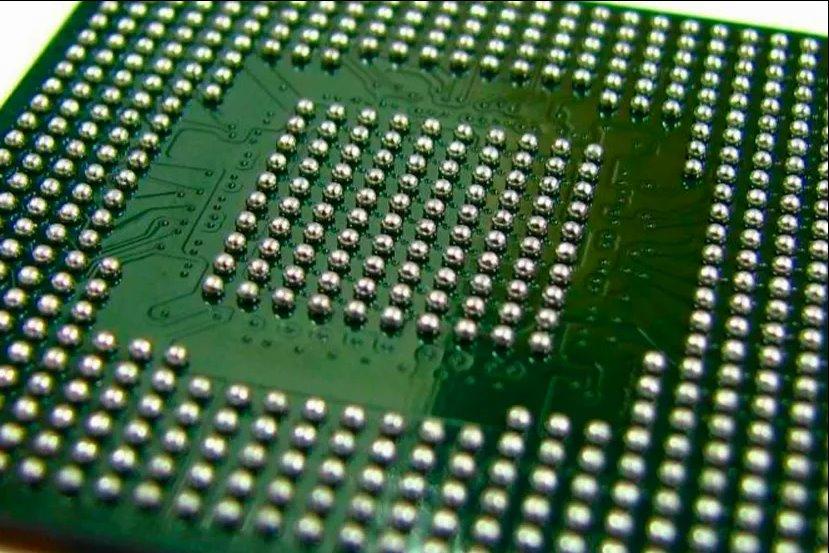

Well, knowing that silicon melts at 1400 ºC, one might think: «Why do processors “shut down” when it reaches 100ºC?» Well, the reason, mainly, is in the Union that exists between DIE of processor or graphics card and PCB. Both elements are created separately and joined by tin.

It is precisely the tin that limits the operating temperature of the processors. The melting temperature approximate of tin It is 230ºC, although it can vary according to the composition of the alloy. Pure tin is not used in the solder, different combinations of materials are used.

We have gone from more than 1400 ºC to approximately 230 ºC, the 100ºC limit. There is still a large margin, one would think that manufacturers could modify the “shutdown” of the chip for its protection at 150 ºC, but it is not recommended at all.

We don’t care that tin melts at 230 ºC, the issue it’s in the weld stress. When a material heats up it expands and when it cools down it contracts. High as “simple” as this generates strong degradation in tin. So much so that many times a graphics card not workingafter being subjected to reballing, works perfectly.

Reballing? What’s that?

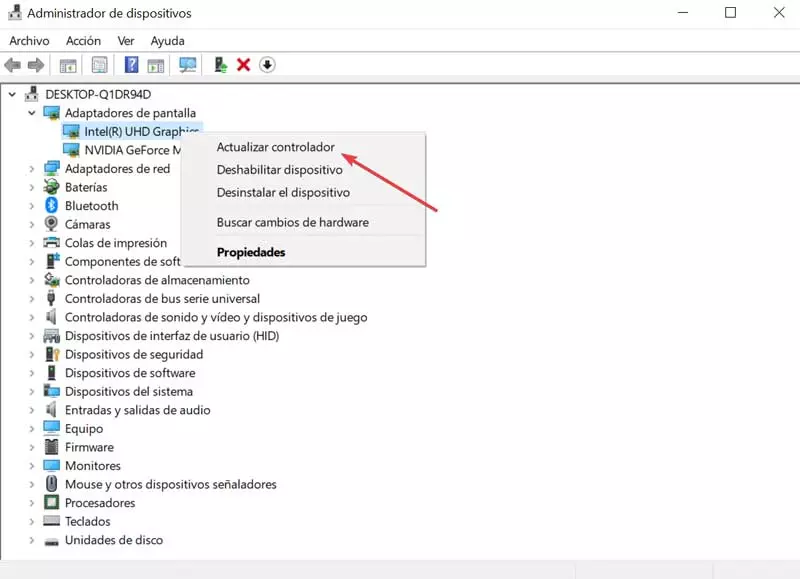

Normally, it is only done on graphics cards, removing the GPU from the graphics PCB. It is not done in processors because it is much more complex and because the tin solder is very small.

Put simply, reballing involves heating the GPU until the tin liquefies and can be removed. Then, all this old tin that did not allow conductivity is removed and replaced with new tin. It heats up again and the weld is now perfect.

Have many problems and difficulties This process. The first requires a very specific machinery and that it is expensive. In addition, it requires some technical knowledge important, so as not to break the graphics or damage the GPU due to excess heat. To finish it off, you need good ventilationsince many times the tin is combined with leadwhich is very toxic.

A bad practice that is used and should notis to do it in a home oven. There are several reasons, but the most important is that a part of the tin and of lead they gasify and stick to the oven walls. Both materials are highly toxic and even if you clean well, these metals can pass into food and when ingested, we would become seriously ill.

Currently, it is what it is

Most likely you think that tin should be replaced by another material. The truth is that there is no better material for the following reasons:

- Tin is very cheap and easy to produce.

- Offers good stability at elevated temperatures (over 50º C)

- It can be shaped quite easily

Unfortunately, we currently do not have an interesting alternative to this material. Other materials are being investigated and some are used, especially for hardware that will be subjected to high thermal stress. But commercially, tin, due to its properties, is the best and most economical solution.